Modern Grey Flooring

In the recent years,grey oak tune has been a trend for the groud flooring decoration choices,and there are always the many choices for SPC Flooring with a wood grain color when you are considering for a certain of floorings that you can achieve both the wood feelings and waterproof factors. JINGDA SPC Flooring will meet all your requirements.

SPC Flooring

Short for stone plastic composite, SPC is designed to identically replicate traditional flooring materials such as stone, ceramic, or wood, yet provide many more practical benefits as you will see later on in the article. Using realistic photographic prints along with a clear, vinyl top layer, SPC opens the door to a wide variety of design concepts.

Classification | Classic | Premium | |

CORE THICKNESS | 4 | 5mm,6mm,7mm,8mm | |

WEAR LAYER | 0.3 | 0.5mm to 0.7mm | |

Sizes | 1220*150/151/152/180/181/182/183/228/229/230 mm | 1220*150/151/152/180/181/182/183/228/229/230 mm | |

BACK LAYER WITH EVA/IXPE | 1.0mm 1.5mm | 1.0mm 2.0mm | |

Surface Finish | Embossed | Registered Embossing | |

BEVEL | Micro | Micro / Painted | |

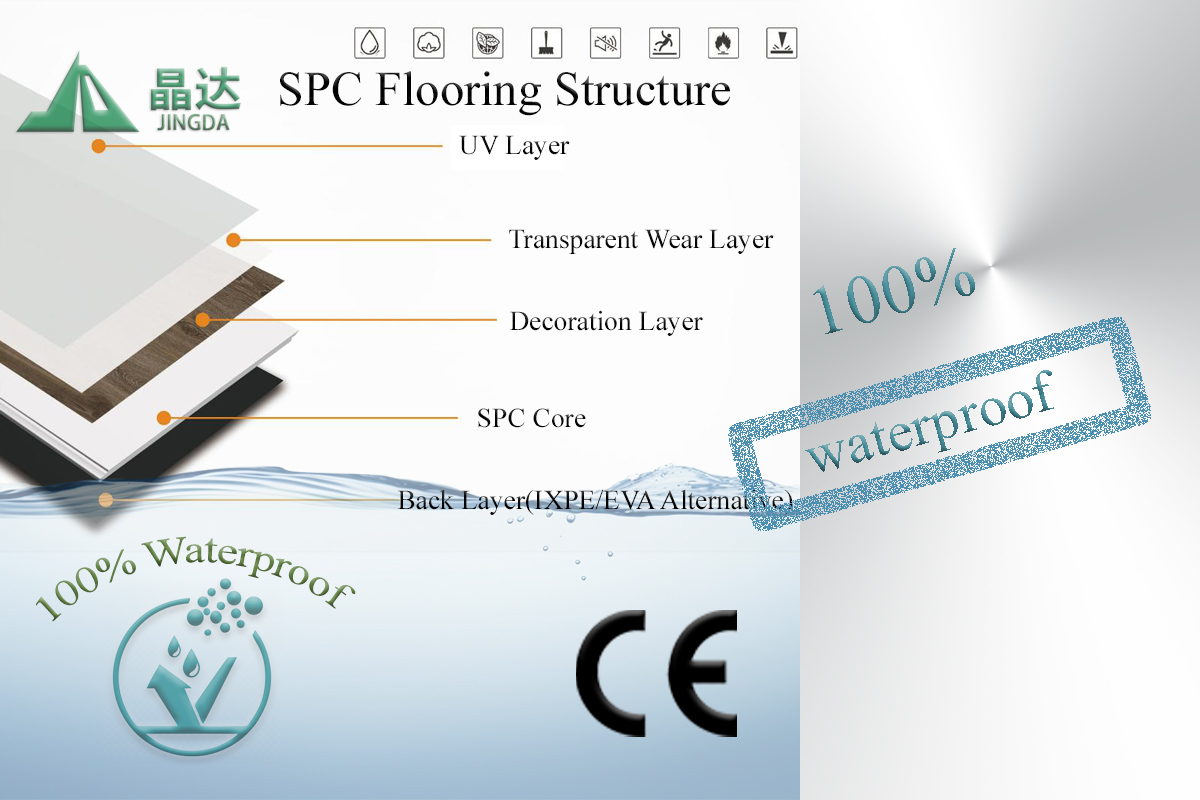

SPC flooring is generally comprised of the four following layers in mind:

Wear Layer — Playing a crucial role in the lifespan of your tiles, this layer uses clear coatings such as aluminum oxide that will keep your floor from rapidly wearing.

Vinyl Top Layer — Certain premium types of SPC come manufactured with realistic, 3D visuals that can be installed to identically resemble stone, ceramic, or wood.

Rigid Core — The core layer is where you get the most bang for your buck. Here, you will find a high density, yet stable waterproof center that provides rigidity and stability to the plank.

Backing Layer — Otherwise known as the flooring’s backbone, this layer provides your planks with added sound installation, as well as being naturally resistant to mold and mildew.

The Manufacturing Process of SPC Flooring

To go the extra mile in understanding SPC flooring, let’s take a look at how it’s made. SPC is manufactured through the following six primary processes.

Mixing

To begin, a combination of raw materials is placed into a mixing machine. Once inside, the raw materials are heated up to 125 – 130 degrees Celsius in order to remove any water vapor inside the material. Once complete, the material is then cooled inside the mixing machine to prevent the occurrence of early plasticization or processing auxiliary decomposition.

Extrusion

Moving from the mixing machine, the raw material then goes through an extrusion process. Here, temperature control is crucial in order for the material to plasticize correctly. The material is ran through five zones, with the first two being the hottest (around 200 degrees Celsius) and slowly declining throughout the remaining three zones.

Calendaring

Once the material is fully plasticized into a mold, it is then time for the material to begin a process known as calendering. Here, a series of heated rollers are used to compound the mold into a continuous sheet. By manipulating the rolls, the width and thickness of the sheet can be controlled with precise accuracy and consistency. Once the desired thickness is reached, it is then embossed under heat and pressure. Engraved rollers apply the textured design onto the face of the product which can be a light “tick” or a “deep” emboss. Once the texture is applied, the scratch and scuff Top Coat will be applied and sent to the drawer.

Drawer

The drawing machine, used with frequency control, is connected with a motor directly, which is a perfect match to the production line speed and is used to deliver the material to the cutter.

Cutter

Here, the material is crosscut to meet the correct guideline standard. The cutter is signaled by a sensitive and accurate photoelectric switch to ensure clean and equal cuts.

Automatic Plate-Lifting Machine

Once the material has been cut, the automatic plate-lifting machine will lift and stack the final product into the packing area for pick-up.

Stone Plastic Composite Flooring

The Benefits of Choosing SPC Vinyl Flooring

Easy installation

SPC can be easily installed in two ways, either with glue or with a loose-lay floor. Using newer loose-lay systems makes it possible to use SPC with minimal surface preparation. With this solution, flooring installation costs, as well as installation time, can be reduced.

Waterproof

One of the biggest benefits of choosing SPC vinyl flooring is that it is completely waterproof. Due to its rigid, PVC core layer, these planks can withstand liquids and spills unlike many of the flooring products that it mimics.

Style and Comfort

SPC has a softer surface than other flooring materials such as wood or stone. It is also more comfortable underfoot and sound-reducing, which is a very important trait for many facilities.

Environmentally Friendly

Choosing SPC can help your facility earn LEED certification, as many of the materials used in its production are those of renewable products, recyclable content, and low-emitting materials.

Budget

Want flooring that is waterproof, scratch, stain a fade-resistant, yet won’t break the bank? Look no further. SPC vinyl flooring is generally less expensive than the luxury floors that it mimics such as hardwood or stone.

Maintenance

SPC never has to be sanded or sealed, making it much easier to maintain than other luxury floors. Since it is completely waterproof, just grab a damp mop and you are all set!

SPC Flooring Advantages:

100% Waterproof: Won't warp or buckle.

Wear Layer-Luxury Vinyl Design Layer

Durable: Provides superior stain resistance and cleanability.

Easy to Install: Angle tap system can be installed easily over existing floors.

Maintenance Free: Protects against excessive wear and stains. Never needs sanding, sealing or refinishing.

Tough: SPC core provides another level of hardcore toughness and durability.

Pre-Attached IXPE/EVA Underlayment

Quiet and Warm:The underlayment blocks out chills and noise.

JINGDA SPC FLOORING LOADING